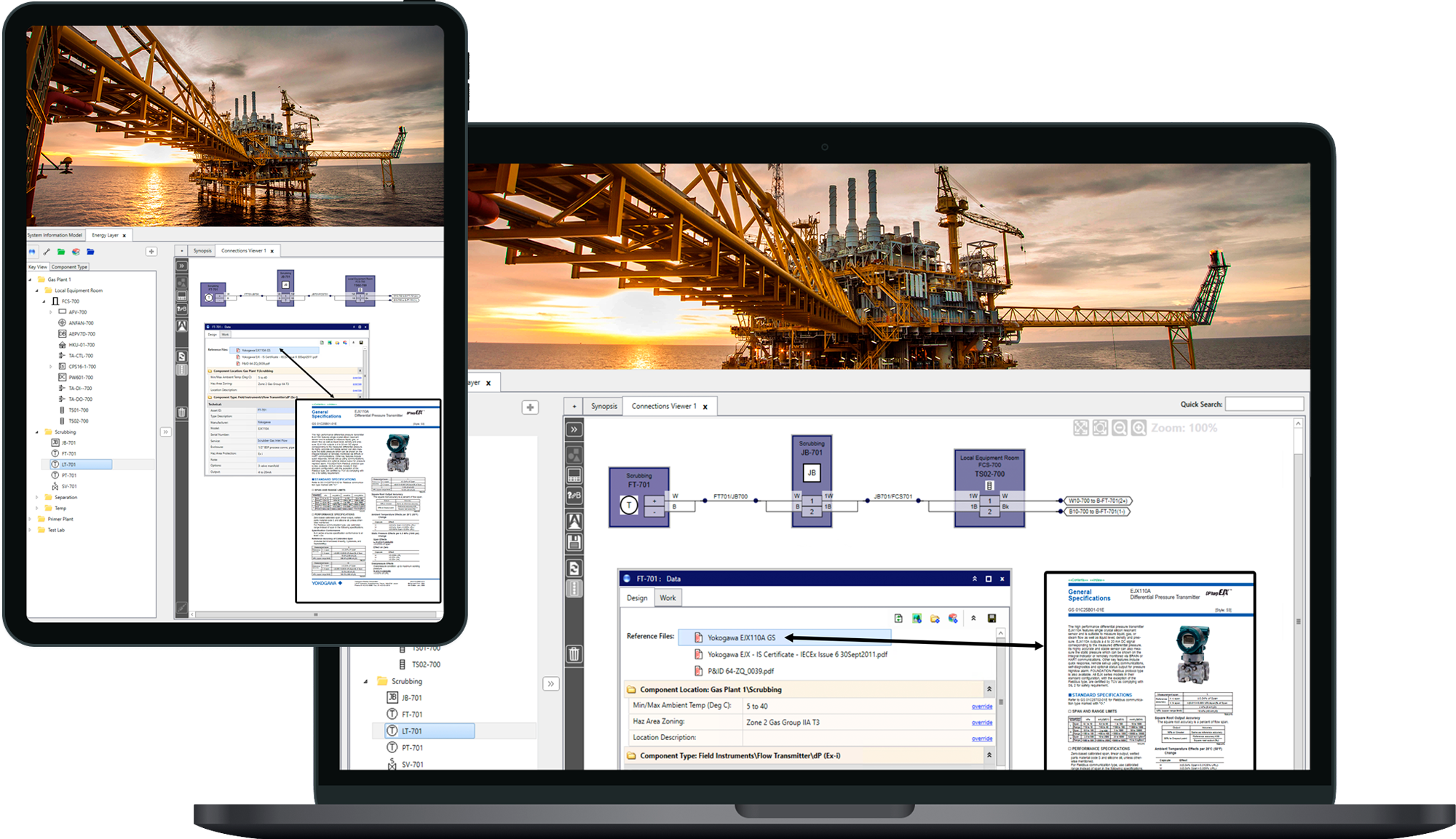

Energy

Asset owners and service providers operating in the critical domain of energy production must fully exploit advances in technology to ensure the future reliability and resilience of the complex systems that drive productivity. To achieve this, systems information must be centralised and digital. So, it’s no surprise that many of our clients in the energy sector discovered dad after struggling to manage the enormous amount of complex data for their projects using traditional decentralised documentation methods.

Contact us to learn more about how dad can provide solutions for the energy industry.