Manufacturing

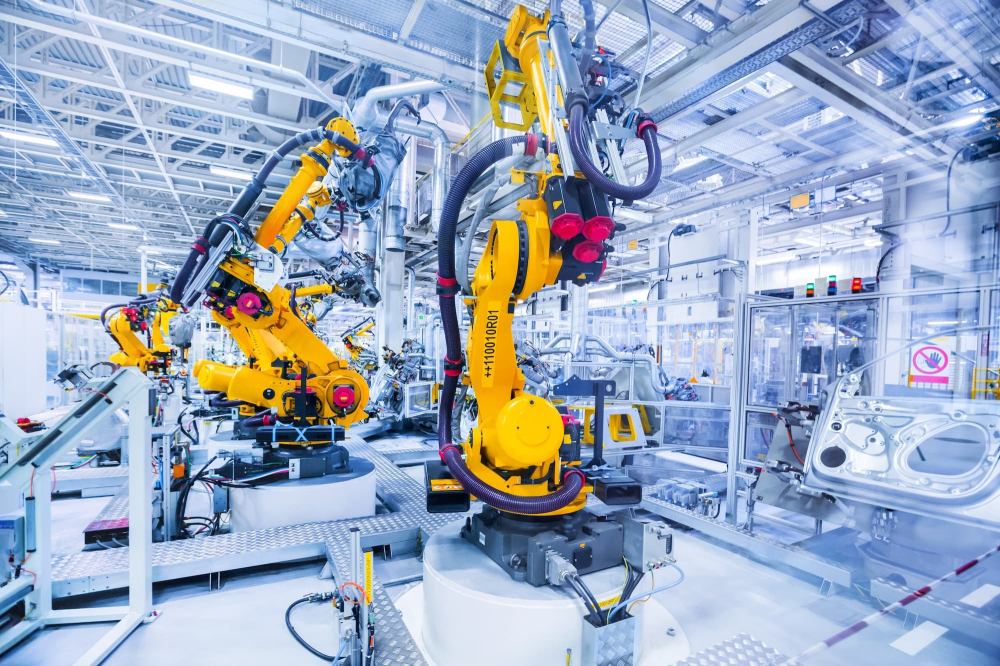

Complex systems in manufacturing encompass advanced manufacturing technologies, automation and robotics, information and communication technologies and supply chain logistics, all of which must be managed efficiently to ensure optimal productivity.

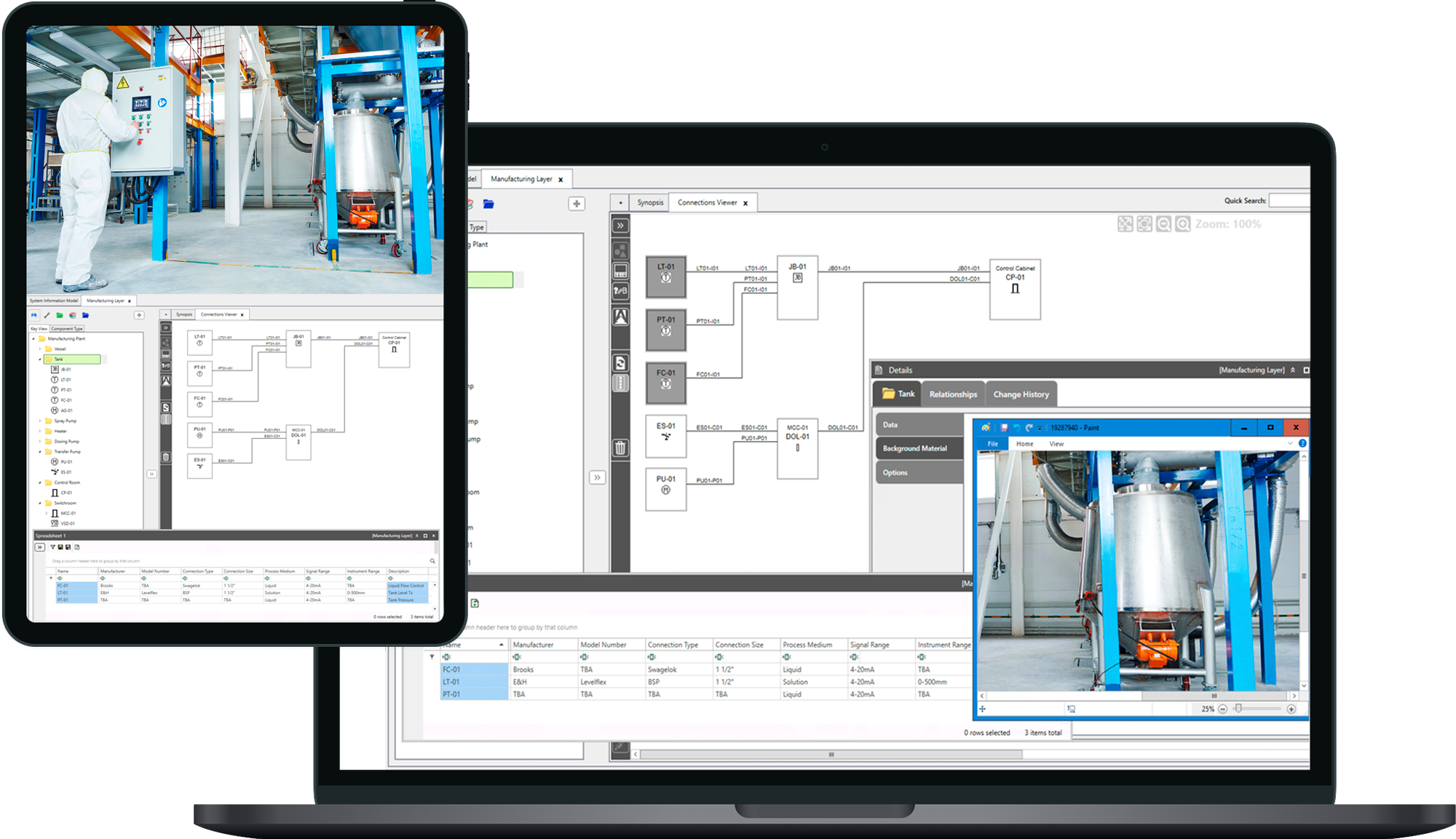

Well designed and managed complex systems are at the heart of efficient and productive manufacturing facilities. Our clients in the manufacturing sector, including Wesfarmers Chemicals, Energy & Fertilisers and Coogee Chemicals, have used dad to engineer and manage new and existing facilities.

Contact us to learn more about how dad can provide solutions for the manufacturing sector