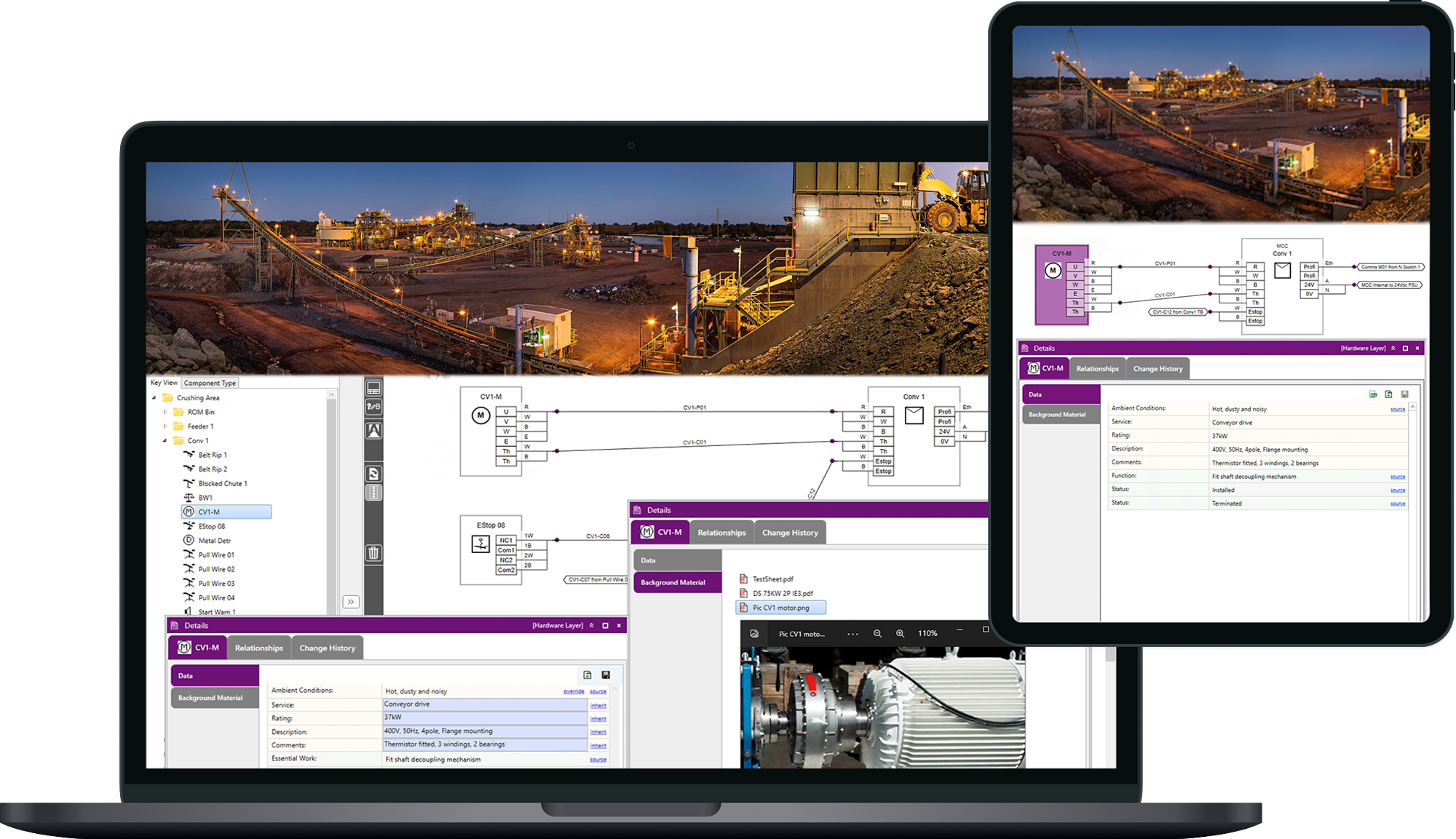

Mining

dad has helped asset owners and service providers in the mining sector transform the way that they design and manage complex systems. The scalability of dad is unparallelled. For over 10 years Fortescue has successfully used dad on their key magnetite projects. dad is also used by engineering consultants to manage minor modifications to smaller projects.

Contact us to learn more about how dad can provide solutions for the mining industry.